DOCUMENTATION AND RESOURCES

Thermotop combines the high thermal performance of PIR boards with the advantages of local production. Manufactured in Romania, our boards are available immediately and can be delivered quickly nationwide or anywhere in South-Eastern Europe, guaranteeing competitive prices, immediate availability, and a reliable partner for all your projects.

What are PIR insulation boards

PIR insulation boards are rigid boards made of polyurethane foam with a closed-cell structure, designed to provide high-performance thermal insulation, high compressive strength, and good fire behavior. The fine structure with gas-filled cells creates an efficient barrier against heat transfer, significantly reducing energy losses. Due to this structure, PIR boards have the highest dimensional stability among all insulation materials, maintaining their mechanical and thermal properties over long periods.

THERMOTOP Advantages

Every project becomes more efficient with Thermotop PIR insulation boards. They contribute to optimizing overall construction costs, reduce heating and cooling expenses, maximize usable space, and are installed quickly and easily. Additionally, their durability transforms any building into an energy-efficient and sustainable space.

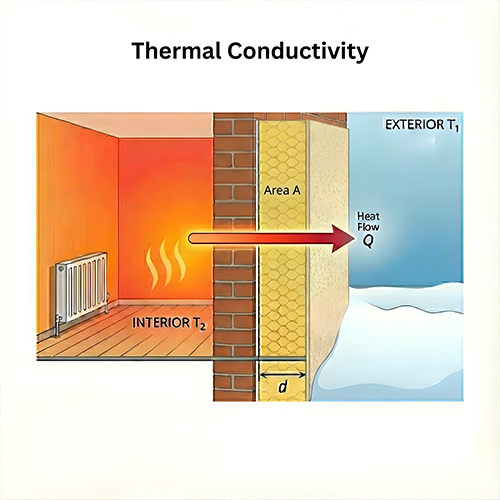

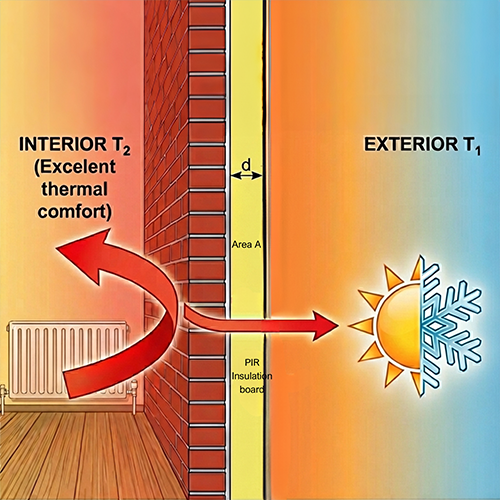

Thermal conductivity

C – Thermal conductivity coefficient (λ, lambda) [W/mK] – is the physical quantity that shows the extent to which a material transmits heat (through thermal conduction). The thermal conductivity coefficient is the amount of energy (heat) transmitted per second (Joule/second, i.e., Watt) crossing a material with a thickness of 1 meter, when there is a temperature difference of 1 Kelvin between its faces. The lower the λ value, the less heat the material conducts and the better its insulating performance.

Thermal transmittance coefficient

U – Thermal transmittance coefficient [W/(m²·K)] = the ability of a material to transfer heat. The lower the U, the better the element insulates.

Calculation formula: U = λ / d

Thermal resistance

Thermal resistance is the ability of a material to oppose heat transfer. The higher the R value, the better the material acts as a thermal insulator, saving more energy.

Thermal bridge

An area in a constructive element or in a joint between elements where thermal insulation is discontinuous or diminished and where energy losses occur between the interior and exterior.

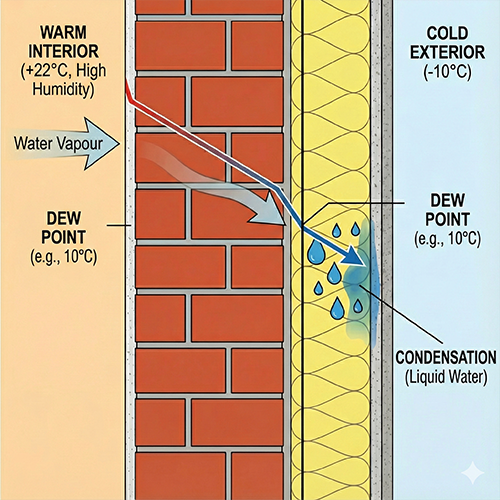

Dew point

The temperature at which water vapors in the air begin to condense and turn into water droplets when the air is cooled at constant pressure.

Air tightness

Represents the ability of a building’s envelope to prevent uncontrolled air circulation through cracks, joints, or non-tight areas. A well-sealed building limits heat loss, prevents condensation and mold formation, reduces energy consumption, and increases thermal comfort.

Thermal insulation is essential in achieving building air tightness. By using THERMOTOP PIR boards, you obtain a continuous barrier against air transfer, due to the “L” type joint. Thus, the risk of infiltration decreases, and the building structure is protected and contributes to maintaining energy performance in the long term.

PIR and other insulation materials

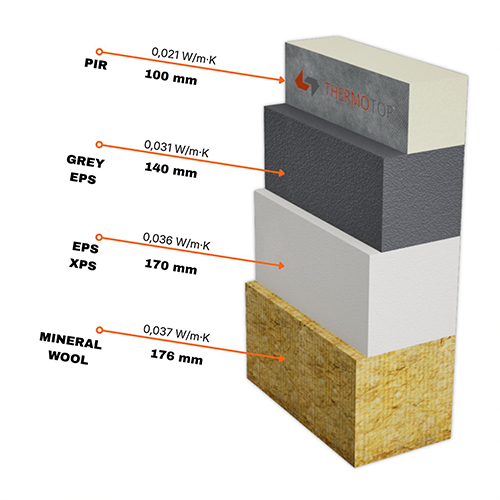

Thermotop insulates better than other traditional materials. A 100 mm THERMOTOP PIR board has a thermal resistance of 4.76; to achieve the same value with traditional materials you need:

176 mm* mineral wool,

170 mm* expanded polystyrene (EPS),

140 mm* graphited polystyrene.

*Values were calculated with a thermal conductivity coefficient of 0.037 W/mK for mineral wool, 0.036 for expanded polystyrene, 0.034 for extruded polystyrene, 0.031 for graphited polystyrene.

PIR and fire safety

Fire safety is essential in any construction project, and at the European level and in Romania, it is well regulated and establishes clear requirements regarding the reaction to fire and fire resistance of materials and constructive systems. Thermotop PIR boards offer high performance due to their structural stability and predictable behavior in case of fire.

Reaction to fire

Reaction to fire concerns how a material behaves or contributes to the development of a fire in the initial phases. Classification is established according to EN 13501-1 and is expressed by a code such as B-s2,d0, C-s3,d0, etc., based on three criteria:

- flammability (A–F),

- smoke production (s1–s3),

- and the formation of flaming droplets/particles (d0–d2).

In the ETICS system, THERMOTOP PIR boards have a B-s1d0 reaction to fire class, being one of the solutions that meet fire safety requirements for building envelopes.

Fire resistance

Fire resistance refers to the performance of a constructive element, a self-supporting structure, in a fully developed fire. According to EN 13501-2, the evaluation includes:

R – load-bearing capacity,

E – integrity,

I – insulation

Thermotop has developed two roof systems for industrial and civil constructions, Thermotop Roof System REI 30 and Thermotop Roof System REI 20, certified with REI30 and REI20 fire resistance.

THERMOTOP PIR boards and energy efficiency standards

Building energy efficiency is regulated at both European and national levels through requirements targeting building envelope performance and energy consumption reduction. THERMOTOP PIR insulation boards are designed to meet these requirements, offering low thermal conductivity and excellent long-term dimensional stability.

With a thermal conductivity coefficient λD ≤ 0.021 W/mK, THERMOTOP PIR boards allow for low U-values of the building envelope elements, directly contributing to meeting nZEB (Nearly Zero Energy Buildings) standards. The main benefits of thermal insulation with THERMOTOP are:

- Optimization of general construction costs

- Reduction of heating/cooling costs for spaces

- Reduction of installation times

- Optimization of material losses

- Resistance and durability for decades

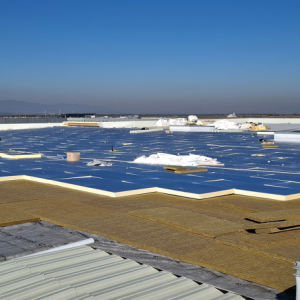

THERMOTOP in projects

Discover projects where insulation becomes part of the final solution

Certifications, technical assessments, and technical documentation

Download the latest certification documents and technical assessments for THERMOTOP PIR boards, as well as product technical documentation and DWG files for thermal insulation systems

DECLARATIONS OF PERFORMANCE

PRODUCT TECHNICAL SHEETS

DWG FILES

- Pitched roof thermal insulation constructive detail between and under rafters

- Pitched roof thermal insulation constructive detail over rafters

- Pitched roof attic slab thermal insulation constructive detail

- Foundation and concrete slab thermal insulation constructive detail

- Heated floor thermal insulation constructive detail

- Non-walkable terrace thermal insulation constructive detail

- Green/Vegetated terrace thermal insulation constructive detail

- Facade thermal insulation system decorative plaster constructive detail

CONSTRUCTIVE DETAILS PDF

- Pitched roof thermal insulation constructive detail between and under rafters

- Pitched roof thermal insulation constructive detail over rafters

- Pitched roof attic slab thermal insulation constructive detail

- Foundation and concrete slab thermal insulation constructive detail

- Heated floor thermal insulation constructive detail

- Non-walkable terrace thermal insulation constructive detail

- Green/Vegetated terrace thermal insulation constructive detail

- Facade thermal insulation system decorative plaster constructive detail

About us

Thermotop is the first manufacturer of PIR thermal insulation boards in Romania, with a 9,000 m² production unit located in Ghimbav, Brașov, being also the largest factory of this type in Southeastern Europe. With an annual production capacity of approximately 6 million m2, we are present on the local market and in six countries in Southeastern Europe, offering high-performance thermal insulation solutions for new constructions and renovations, in the civil, commercial, industrial or agricultural fields.

Our products are designed to meet the highest standards in the field of thermal insulation, playing an essential role in reducing energy consumption and maximizing thermal comfort, directly contributing to the sustainable development of the construction field.

We are committed to using the most advanced production technologies, with minimal impact on the environment. Care for the environment and respect for our customers and partners are fundamental at every stage of the production process – principles that guide us in strengthening our role as a responsible leader in the thermal insulation materials industry.

The first PIR board factory in Romania

Opened in 2025, THERMOTOP is the largest PIR production unit in Southeastern Europe

Premium thermal insulation solutions

We produce solutions for reducing energy consumption and increasing thermal comfort

Sustainability

Advanced technology with minimal environmental impact and respect for the future

6.000.000 m2

Annual production capacity of PIR thermal insulation boards

Discover more