Products and applications

Every project becomes more efficient with Thermotop PIR thermal insulation boards. They help optimize overall construction costs, reduce space heating/cooling costs, maximize usable space and are quick and easy to install. In addition, their durability transforms any building into an energy-efficient and sustainable space.

Discover all types of THERMOTOP PIR boards and compatible applications.

THERMOTOP products

Explore the range of Thermotop PIR thermal insulation boards (λ = 0.021 W/mK), available in thicknesses between 20 and 200 mm and with various support layers – membranes or foils – adapted to residential and non-residential applications. Choose the right solution for your project.

Thermal insulation systems with PIR boards

Thermotop PIR thermal insulation boards (λ = 0.021 W/mK) are a high-performance thermal insulation solution used in civil, commercial, industrial and agricultural projects. Regardless of the type of project, they increase the thermal performance of the building, contribute to reducing operating costs and increase the durability of the building.

They are suitable for both new buildings and rehabilitation works, being used in applications such as: Foundation and under concrete slab thermal insulation; Floors, belts, attics; Exterior and interior walls; Roofs with trusses and terrace roofs; Cold and heated floors; Industrial roofs and cold rooms.

Insulate with PIR thermal insulation boards

PIR foam has one of the lowest thermal conductivity coefficients, having been used for decades in industries where thermal efficiency is essential – aeronautics, refrigeration, naval/offshore industry, etc.

Due to its high thermal insulation capacity at a reduced thickness, PIR foam is used in the walls of refrigeration and freezing equipment, in aircraft construction, as well as in industrial applications where thermal performance is essential.

With the evolution of construction standards and the introduction of nZEB (near Zero Energy Buildings) requirements, the need for high-performance thermal insulation solutions has become essential. Classic thermal insulation solutions can achieve the required performance levels, but with greater thicknesses, with an impact on costs and durability over time.

Thermotop responds to these requirements with rigid thermal insulation boards made of PIR foam which, thanks to the very low coefficient of thermal conductivity (λ = 0.021 W/mK), ensures a thermal performance almost double that of conventional materials at the same thickness, with increased durability and reduced maintenance costs.

Frequently asked questions

What is the difference compared to basalt mineral wool?

- Lower weight per square meter

- Does not absorb water

- Easy handling and installation in any weather (can be installed even in rainy conditions)

- Lower insulation costs

What do I need to know about handling and storage?

There are no strict rules or requirements regarding the handling and storage of THERMOTOP insulation boards. These boards are supplied in plastic packaging, equipped with labels containing essential information about the board size, quantity, substrate type, and board thickness.

Are there any restrictions regarding the surfaces for application or installation (flooring, exterior walls, interior walls, roofs, etc.)?

There are no restrictions as long as the appropriate type of THERMOTOP board (with the corresponding support faces) is chosen.

What is the lifespan?

When the correct application procedures are followed, THERMOTOP boards have a long lifespan. Furthermore, the presence of these boards does not have a negative impact on the lifespan of thermally insulated construction elements according to recommended methods; on the contrary, they can bring significant benefits. For example, in the case of wooden elements such as pitched roofs or attics, THERMOTOP boards can contribute to long-term wood protection.

What are the main advantages compared to mineral wool and polystyrene?

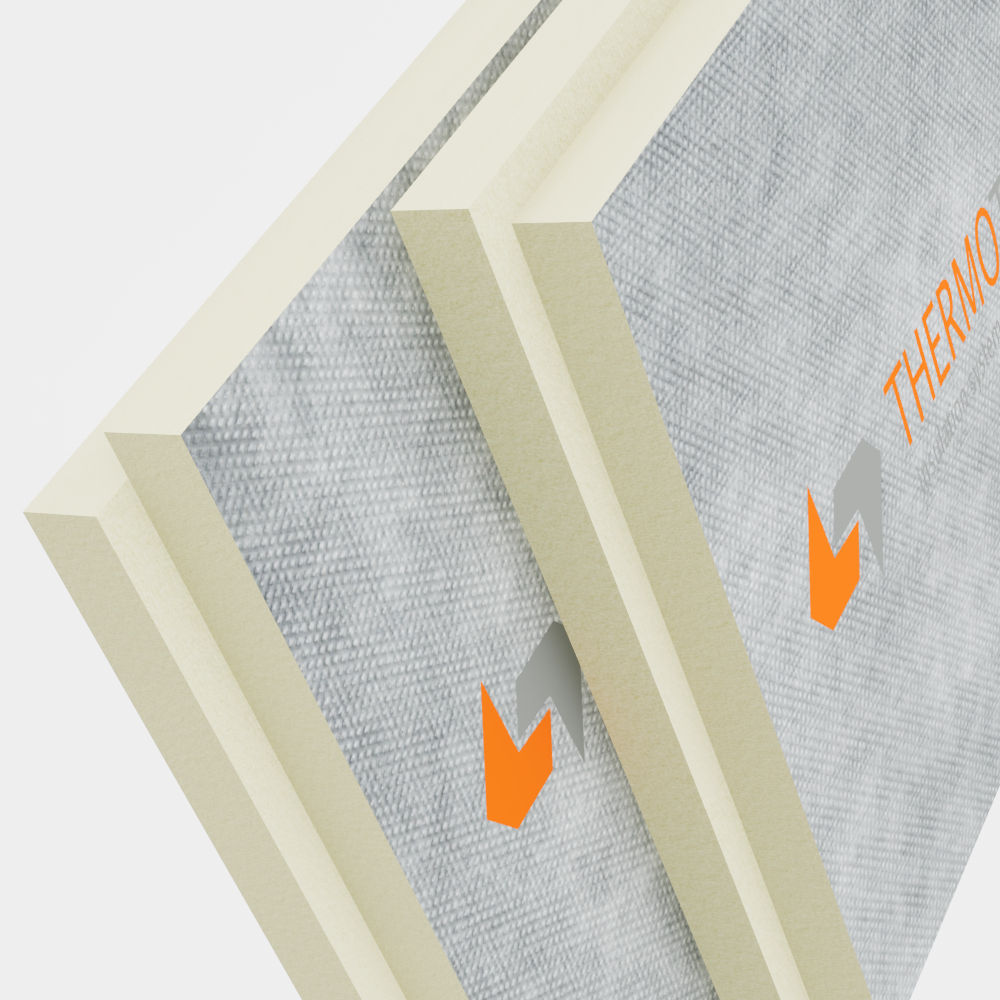

- Reduced thickness of the boards compared to the provided thermal insulation (in terms of thermal resistance, a THERMOTOP board with a thickness of 50 mm is equivalent to an expanded polystyrene board with a thickness of approximately 100 mm or to a concrete block wall with a thickness of approximately 700 mm);

- They allow for various options and combinations of support for the foam (Aluminum foil – AL, vapor barrier – DV) depending on the insulated construction element;

- By choosing the appropriate foam support, very good protection performance against vapors and humidity can be achieved;

- Easy handling and installation;

- Non-existent thermal bridges at the junction between adjacent boards around the perimeter due to the joint ensuring thermal insulation continuity.

Where is it used (where can it be applied)?

In the thermal insulation of various construction elements, such as:

- Floors;

- Attic floors;

- Ceiling cladding;

- Interior wall cladding;

- External facade thermal insulation;

- Sandwich-type insulation – cavity walls with insulation;

- Walkable/ non walkable terrace roof insulation;

- Framed roof insulation, attics;

- Insulation of panels from ground level for industrial and agricultural halls, etc.

What is the difference compared to polystyrene?

THERMOTOP plates differ from traditional polystyrene in the following aspects:

- They have superior mechanical strength compared to expanded polystyrene and comparable mechanical strength to extruded polystyrene.

- They have a much lower thermal conductivity coefficient.

- THERMOTOP boards are suitable for use in both outdoor and indoor spaces.

What are they used for?

THERMOTOP boards are used for thermal insulation of various building elements in civil buildings (houses, apartment blocks, commercial spaces, schools, hospitals, etc.) or in industrial and agricultural buildings (industrial halls with prefabricated concrete structure, industrial halls with metal structure, etc.).